The first experiment to be run at ISIS as part of a large EU project, ReMade@ARI, on materials for the circular economy, has just been completed.

Researchers Denis Kuznetsov and Valentina Vogt from ETH Zurich in Switzerland applied through ReMade to use the Polaris diffractometer at ISIS as part of their work exploring the development of new catalysts. Catalysts are used in many industrial processes to produce the materials we need for daily life, including fuels and feedstocks. These processes can often be very energy-intensive, so finding ways to make them more sustainable is important. Development of new catalyst materials is part of the solution.

Left: Valentina Vogt and Denis Kuznetsov (middle, right) at ISIS as part of ReMade studies of catalysis materials. Yi Zhang, left, works at ISIS to help visiting researcher such as Denis and Valentina get the best from their ReMade experiments.

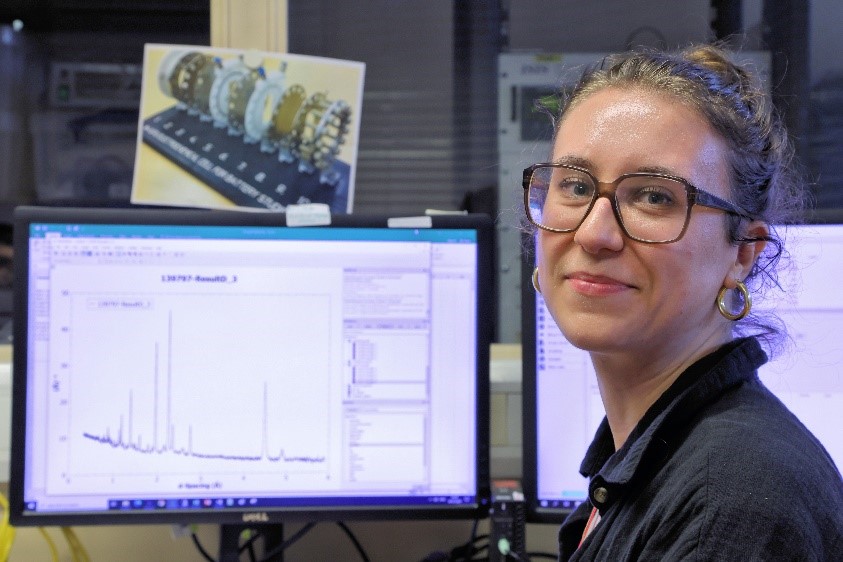

Right: Valentina Vogt with Polaris neutron diffraction data at ISIS as part of ReMade studies of catalysis materials

Denis and Valentina used Polaris to explore metal oxide materials which have the potential to act as catalysts and provide more sustainable processes. The details of the way these materials work at the atom-level aren’t yet understood, but neutron diffraction is very good at looking at light elements, such as oxygen. The aim of the Polaris experiment was to better understand the atomic-level behaviour of the oxygen atoms during catalytic reaction and so add to the picture of the catalysis mechanism.

The study will also involve electron microscopy and X-ray studies at other European facilities, as well as a return to ISIS later this year to use the Wish diffractometer. All these experiments will help to build up a detailed understanding of the catalyst behaviour and how it might contribute to more sustainable processes for producing the things we need for our daily lives.