Technology Readiness Levels in the impact assessment of ReMade@ARI

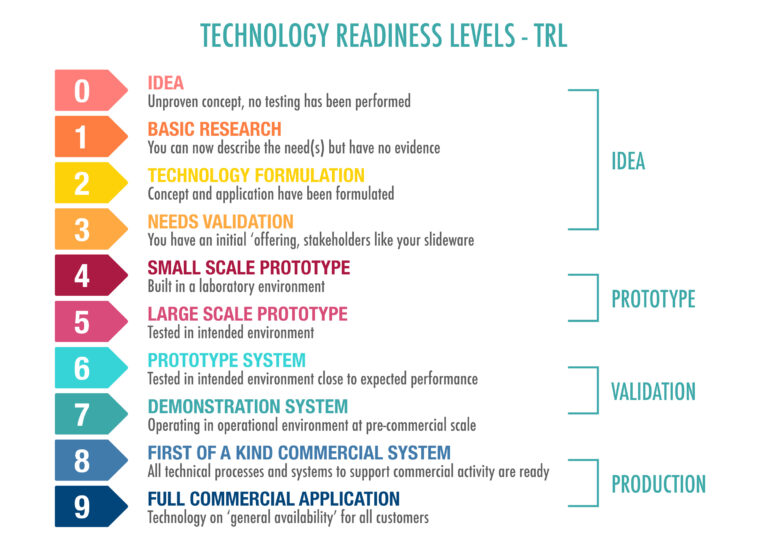

The impact assessment team of ReMade@ARI uses the Technology Readiness Level (TRL) framework among other measures to investigate how the project helps users advance their materials toward practical applications. By categorizing a material’s current TRL, the team gains insights into its readiness for use in the circular economy and identifies the steps needed for further development, ultimately assessing ReMade@ARI’s effectiveness in supporting users’ goals and advancing material sciences towards the circular economy.

TRL is a method that gauges the maturity of a technology, from initial research to full deployment in real-world applications. Originally developed by NASA, the TRL scale is now widely used across various industries and by research funders to assess how close a technology is to industrial use and commercial application. The European Commission introduced the scale during the Horizon 2020 Framework Programme.

The scale ranges from TRL 1, where initial concepts and fundamental research are established, to TRL 9, where the technology has been fully tested and is ready for widespread implementation.

TRL 1 marks the initial stage where basic principles of the material or technology are observed and reported. At this stage, a scientist might be exploring fundamental scientific concepts, such as the underlying chemistry of a new material or discovering novel properties through theoretical research or literature review.

At TRL 2, the focus is on formulating and studying basic material concepts. Researchers begin analyzing individual material components to understand their properties, laying the groundwork for further development. This involves initial identification of key material components and assessing their potential applications.

TRL 3 involves more detailed experimentation and characterization of the material’s properties. Researchers isolate and study the material’s physical, chemical, or mechanical properties to determine its potential usefulness, providing a stronger foundation for future advancements.

At TRL 4, laboratory trials are conducted to demonstrate the feasibility of the material based on its component properties, indicating its potential for practical application. Here, scientists might synthesize a small batch of the material in the lab and perform initial tests to validate its expected behavior, such as testing its strength, conductivity, or thermal resistance under controlled conditions.

TRL 5 involves investigations that integrate basic material components, demonstrating their compatibility and functionality when combined into a working system. A scientist at this stage might combine different components of the material into a prototype composite, testing how they work together, such as creating a multilayered material or incorporating the material into a small device to assess its overall performance.

At TRL 6, testing of material components occurs in controlled environments that mimic real-world conditions, allowing for the assessment of performance in practical scenarios. For example, researchers might expose the material to simulated environmental conditions like extreme temperatures, humidity, or mechanical stress to observe how it performs in situations it would face in actual use.

TRL 7 contains the development of a prototype material, which operates in realistic environments. This provides critical data on properties and performance under near-operational conditions. A scientist at this level might create a full-scale prototype and test it in a relevant environment, such as using a new construction material in a small building or incorporating a material into a functioning electronic device to evaluate its real-world application.

At TRL 8, a manufacturable version of the material is created that meets operational requirements during testing, showing its readiness for real-world application. At this stage, researchers could work on scaling up the production process, ensuring that the material can be manufactured consistently and at the required quality, such as refining the production technique to meet industrial standards.

At TRL 9, the material reaches its final form and demonstrates consistent properties and performance under expected conditions. Extensive field testing and validation in real-world applications confirm its reliability, paving the way for commercial deployment or widespread use. A scientist involved at this stage might oversee the final testing phase in actual operational settings, such as deploying the material in commercial products, buildings, or infrastructure, ensuring it performs as expected across various applications.